0102030405

Mochini oa ho Etsa Palo ea Konkreite e chitja

likarolo tse ka sehloohong

Pole ea motlakase ea konkreite Molao-motheo oa Tšebetso

1) Ho eketsa slurry ka har'a hlobo, e khannoa ka potlako 'me e potoloha ka lebelo le tšoanang la mochine. Karolo e 'ngoe le e' ngoe e arotsoe 'me e lokolloa tlas'a matla a centrifugal. Hangata ha lebelo la ho potoloha le slurry le phahame, ho na le phello e ntle ea ho arola seretse.

2) Sedimentation ea Centrifugal ke ts'ebeliso ea sekhahla se fapaneng sa karolo e 'ngoe le e' ngoe ho slurry, e potolohang tlas'a matla a centrifugal. Ho lemoha karohano ea metsi - a tiileng (kapa a metsi - metsi).

3) Lebelo la karohano lea lieha ha viscosity ea slurry e phahame.

4) Ho molemo bakeng sa sedimentation ea centrifugal ha slurry density e fapane karolong ka 'ngoe.

Melemo ea hlobo ea konkreite ea centrifugal:

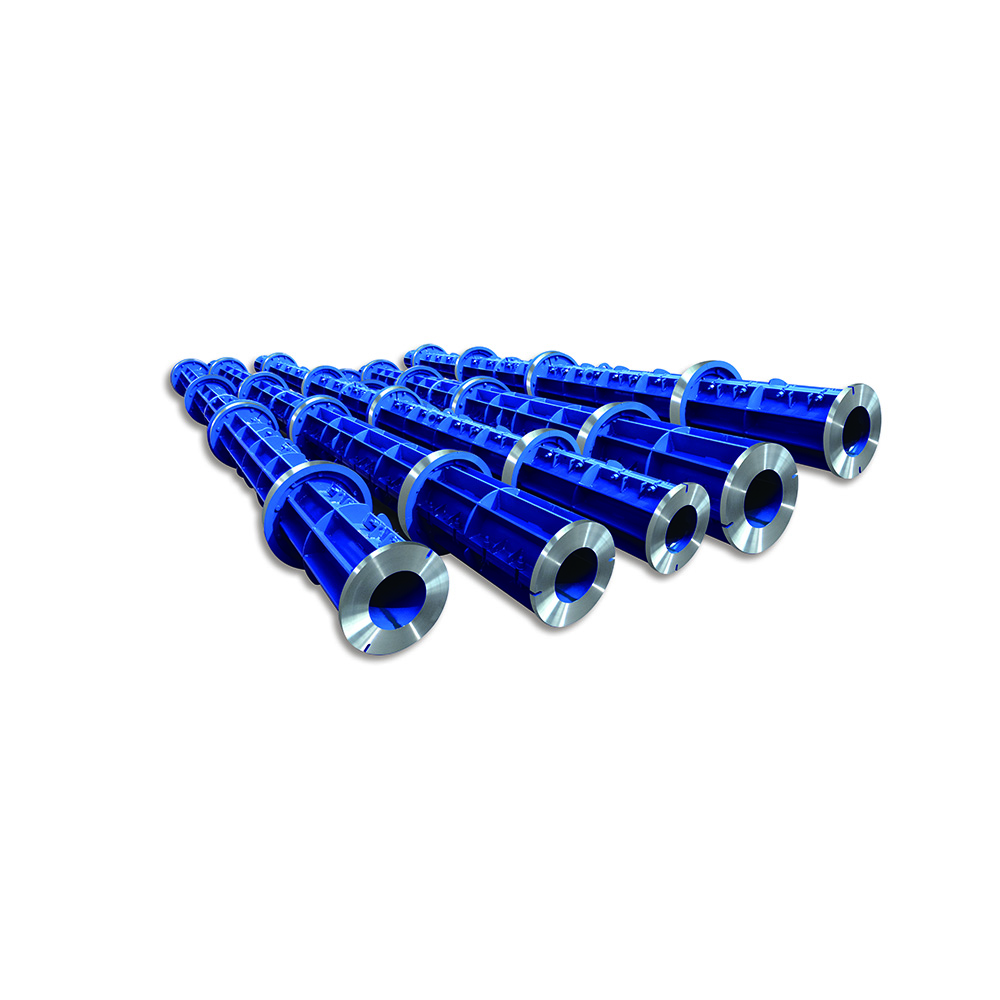

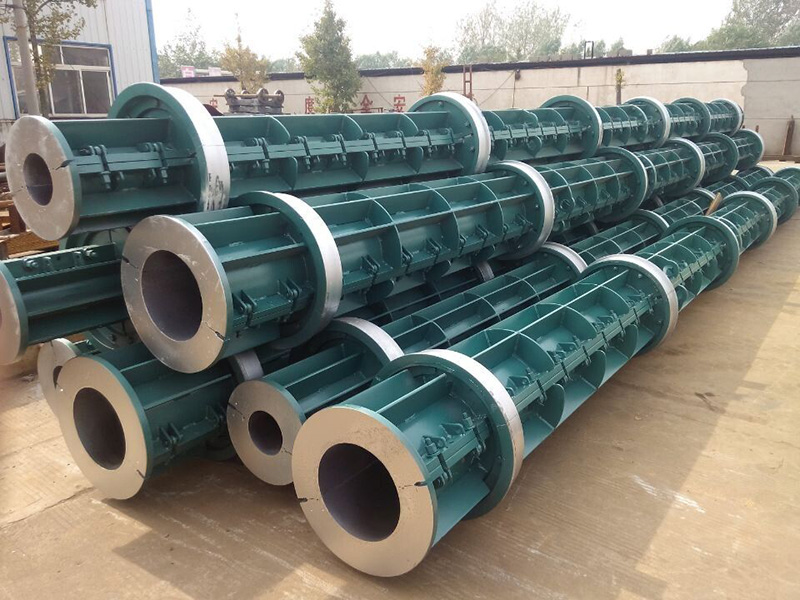

1.'Mele oa cylinder: Thepa e koetsoeng ho latela mohlala oa odara ea moreki, The Maximum single length ke 12m, 'me 'mele oa silinda o na le li-welding seams tse fokolang, tse fokotsang tšusumetso ea deformation ea welding le phoso ea docking ka letsoho.

2.Running wheel: Thepa e amoheloa ka 30Mn ho etsa moqolo o batang, o nang le khanyetso e ntle ea ho apara.

3. Welding: Ho eletsoa ho amohela ts'ebetso ea ho tjheseletsa karolo, mokhoa oa welding ke carbon dioxide shielded welding, khase ke khase e tsoakiloeng, 'me mochini oa welding o amohela mochini oa welding oa Panasonic, sebaka sa welding se setle,' me ha ho na slag ea welding. .

4.Lathe: Hlahisa CW61180L-16m ultra-long lathe, ∅1000mm×15.4M le litlhaloso tse ka tlase li bulehile bakeng sa ts'ebetso ka kakaretso, 'me concentricity ea hlobo ea tšepe e molemo.

5.Anti-leakage grout: Khampani ea rona e sebelisa planer bakeng sa groove lenonyeletsong pakeng tsa hlobo e ka holimo le 'mele,' me lesela la rabara le tiisang le kenngoa ka har'a groove. Lesela lena la rabara le ka sebelisoa hape kapa la nkeloa sebaka ka nako efe kapa efe. Felisa bothata ba ho lutla ha lenonyeletso la fatše.

Mohala oa lihlahisoa

Tekheniki parameter ea pole spinning mochini

| Che. | Ntho | Yuniti | Mohlala | ||

| Mabili a mabeli | Mabili a mararo | ||||

| 1 | Khoele ea lebili | 2000 | 2000 | ||

| 2 | Motheo oa mabili | mm | 950 | 950 | |

| 3 | Lebili le palameng bophara ba kantle | mm | 600 | 600 | |

| 4 | Bophara ba lebili la ho palama | mm | 84 | ||

| 5 | Angelα pakeng tsa setsi sa mabili le mola oa litsi tsa hlobo | (°) | 75°-110° | ||

| 6 | Max.Bolelele ba palo ea konkreite e bopang | m | 26 | 26 | |

| 7 | Max.diameter ea ho bopa konkreite palo | Qetello ea molamu oa conical | mm | 500 | 500 |

| Molamu o lekanang oa bophara | mm | 600 | 600 | ||

| 8 | Matla a motlakase | km | 45kw | 55kw | |

| 9 | Lebelo la lebelo la shaft ea ho qetela ea drive | rpm | 60-1000 | 60-1000 | |

| 10 | Shaft bophara | mm | 130 | 130 | |

| 11 | Lintho tsa motheo | Tšepe ea ho akhela | Tšepe ea ho akhela | ||

| Bophara ba ka hare ba ntlha e ka holimo(mm) | Bolelele(m) | Bophara ba Wheel Lemao(mm) | Tlela(mm) |

| 150 | 6-11 | 600 | 2000 |

| 190 | 7-15 | 600 | 2000 |

| 230 | 6-12 | 650 | 2000 |

| 270 | 6~10 | 650 | 2000 |