0102030405

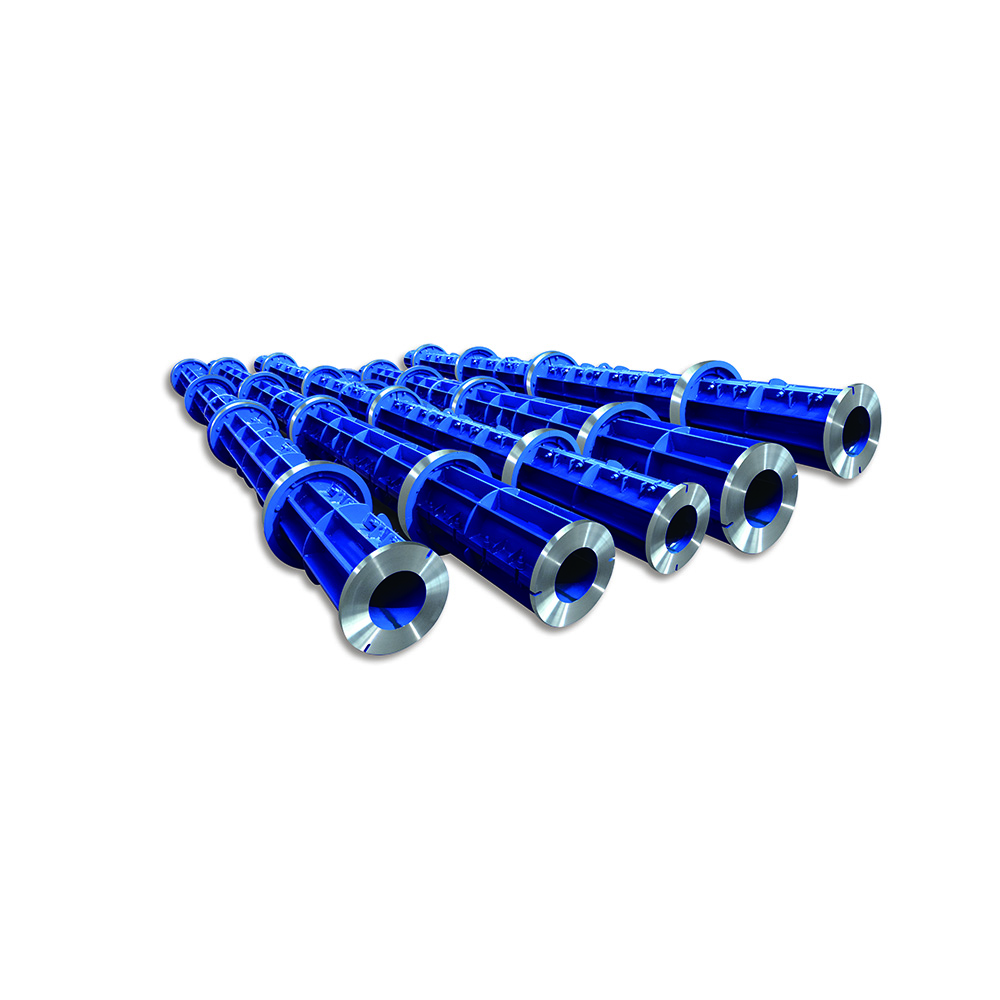

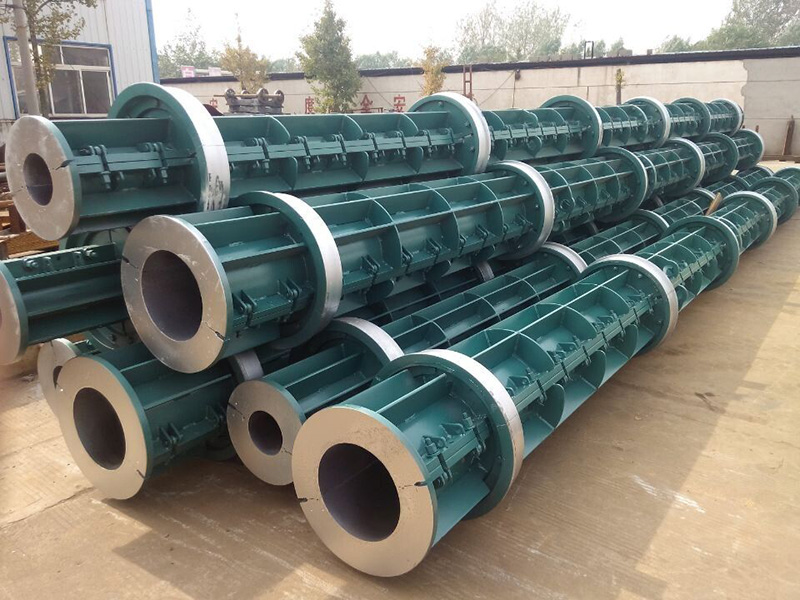

Umtshini wokwenza iPali yeConcrete eRound

iimpawu eziphambili

Ipali yombane ebambekayo uMgaqo wokuSebenza

I-1) Ukongeza i-slurry kwi-mold, iqhutywe ngokukhawuleza kwaye ijikelezwe kwisantya esifanayo somatshini. Icandelo ngalinye lihlulwe kwaye likhutshwe phantsi kwamandla e-centrifugal. Ngokuqhelekileyo okukhona ukuphakama kwesantya sokujikeleza kunodaka, kokukhona isiphumo sokwahlula ludaka lungcono.

I-2)I-sedimentation ye-Centrifugal kukusetyenziswa kobuninzi obuhlukeneyo becandelo ngalinye kwi-slurry, ejikelezwa phantsi kwamandla e-centrifugal. Ukuqonda ukwahlulwa kolwelo - okuqinileyo (okanye ulwelo-ulwelo).

3) Isantya sokwahlula sicotha xa i-viscosity ye-slurry iphezulu.

I-4)Ilungile kwi-sedimentation ye-centrifugal xa ukuxinana kwe-slurry kwahlukile kwicandelo ngalinye.

Izinto eziluncedo zokungunda kwepali yekhonkrithi esentrifugal:

I-1.Umzimba we-cylinder: Izinto ezingenanto ngokuhambelana nemodeli yomyalelo womthengi, Ubude obuphezulu obunye yi-12m, Kwaye umzimba we-cylinder unee-welding seams ezincinci, ezinciphisa impembelelo ye-welding deformation kunye nempazamo yokwenza i-docking manual.

Ivili le-2.Running: Izinto ezisetyenziswayo zamkelwe i-30Mn ebandayo yokwenza umqulu, kunye nokumelana nokunxiba kakuhle.

I-3.I-Welding: Kucetyiswa ukuba uthabathe inkqubo ye-welding yecandelo, indlela ye-welding yi-carbon dioxide shielded welding, i-gas ixutywe ngegesi, kwaye umatshini we-welding wamkela umatshini we-welding we-Panasonic, indawo ye-welding intle, kwaye akukho slag ye-welding. .

I-4.Lathe: Yazisa i-CW61180L-16m i-ultra-long lathe, ∅1000mm× 15.4M kunye neenkcukacha ezingezantsi zivulekele ukusetyenzwa ngokubanzi, kwaye ukugxila kwe-mold yensimbi kungcono.

I-5.I-Anti-Leakage grout: Inkampani yethu isebenzisa iplani ye-groove kwindawo edibeneyo phakathi kwe-mold ephezulu kunye nomzimba, kunye nomcu werabha otywiniweyo ufakwe kwi-groove. Lo mcu werabha ungaphinda usetyenziswe okanye utshintshwe nangaliphi na ixesha. Ukuphelisa ingxaki yokuvuza ngokubambisana komhlaba.

Umgca wemveliso

Ipharamitha yobugcisa yomatshini wokujikeleza

| Hayi. | Into | Iyunithi | Umzekelo | ||

| Ivili eliphindwe kabini | Amavili amathathu | ||||

| 1 | Umsonto wevili | 2000 | 2000 | ||

| 2 | Isiseko samavili | mm | 950 | 950 | |

| 3 | Ivili lokukhwela idayamitha yangaphandle | mm | 600 | 600 | |

| 4 | Ukukhwela ivili ububanzi | mm | 84 | ||

| 5 | Angelα phakathi iziko ivili kunye nomgca amaziko ngundo | (°) | 75 ° -110 ° | ||

| 6 | Ubuninzi. Ubude bepali yekhonkrithi yokubumba | m | 26 | 26 | |

| 7 | Ubukhulu bepali yekhonkrithi yokubumba | Ukuphela kwentonga yeconical | mm | 500 | 500 |

| Intonga yedayamitha elinganayo | mm | 600 | 600 | ||

| 8 | Amandla emoto | km | 45kw | 55kw | |

| 9 | Uluhlu lwesantya seshaft yokugqibela yokuqhuba | rpm | 60-1000 | 60-1000 | |

| 10 | Idayamitha yomngxuma | mm | 130 | 130 | |

| 11 | Izinto zesiseko | Intsimbi yokugalela | Intsimbi yokugalela | ||

| Idayamitha yangaphakathi yesiphelo esiphezulu(mm) | Ubude(m) | Ububanzi bevili elibalekayo(mm) | Tyala(mm) |

| 150 | 6-11 | 600 | 2000 |

| 190 | 7-15 | 600 | 2000 |

| 230 | 6-12 | 650 | 2000 |

| 270 | 6~10 | 650 | 2000 |