0102030405

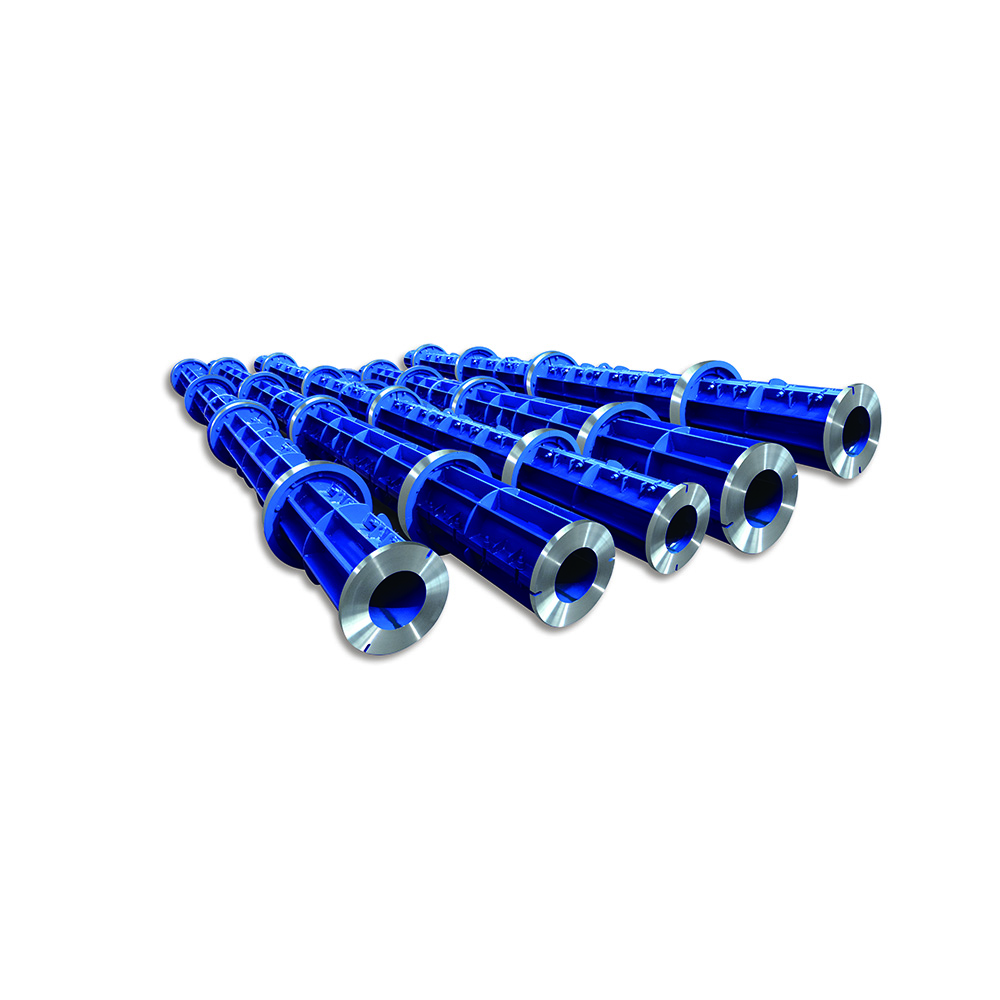

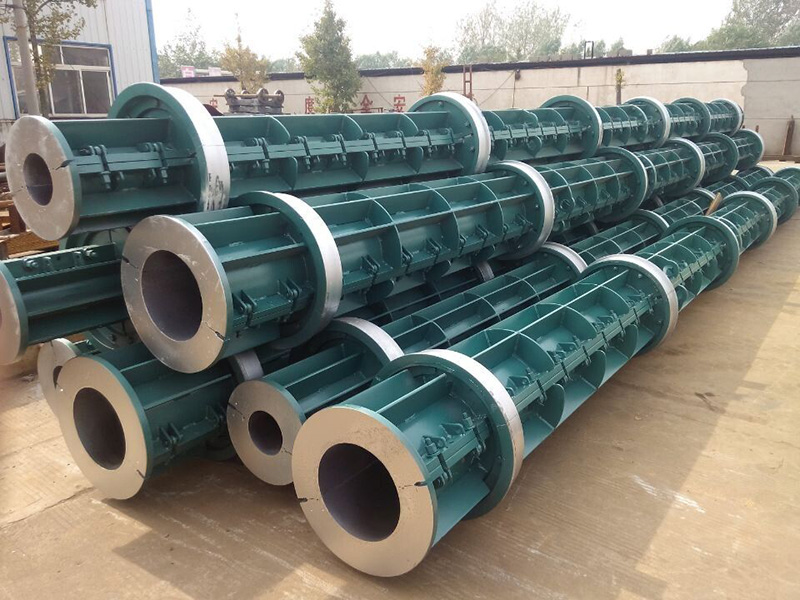

Umshini Wokwenza Izigxobo Eziyindilinga

izici eziyinhloko

Isimiso sokuSebenza sesigxobo sikagesi sikakhonkolo

1) Ukwengeza i-slurry esikhunjeni, iqhutshwa ngokushesha futhi ijikelezwe ngesivinini esifanayo somshini. Ingxenye ngayinye ihlukaniswa futhi ikhishwe ngaphansi kwamandla we-centrifugal. Ngokuvamile ukuphakama kwesivinini sokuzungezisa udaka, kuba ngcono ukuhlukanisa umthelela wodaka.

2)I-centrifugal sedimentation ukusetshenziswa kokuminyana okuhlukile kwengxenye ngayinye ku-slurry, ezungeziswa ngaphansi kwamandla we-centrifugal. Ukubona ukwahlukaniswa koketshezi - okuqinile (noma okuwuketshezi - okuwuketshezi).

3) Ijubane lokuhlukanisa lihamba kancane lapho i-viscosity ye-slurry iphezulu.

I-4)Kuhle ku-centrifugal sedimentation lapho ukuminyana kwe-slurry kuhlukile engxenyeni ngayinye.

Izinzuzo zokubunjwa kwesigxobo sikakhonkolo se-centrifugal:

I-1.Umzimba wesilinda: Impahla evaliwe ngokwemodeli ye-oda lekhasimende, Ubude obungakodwa obukhulu buyi-12m, Futhi umzimba wesilinda unezithunge zokushisela ezincane, okunciphisa umthelela we-welding deformation kanye nephutha le-docking manual.

I-2.Isondo eligijimayo: Izinto ezisetshenziswayo zamukelwa ukwakhiwa kwe-roll ebandayo engu-30Mn, enokumelana nokugqokwa okuhle.

I-3.I-Welding: Kunconywa ukuthi usebenzise inqubo ye-welding yesigaba, indlela yokushisela i-carbon dioxide shielded welding, igesi iyigesi exutshwe, futhi umshini wokushisela usebenzisa umshini wokushisela we-Panasonic, indawo yokushisela yinhle, futhi ayikho i-slag yokushisela. .

I-4.Lathe: Yethula i-CW61180L-16m i-ultra-long lathe, ∅1000mm×15.4M nezicaciso ezingezansi zivulekele ukucutshungulwa sekukonke, futhi ukugxila kwesikhunta sensimbi kungcono.

5.I-Anti-Leakage grout: Inkampani yethu isebenzisa iplanethi ukuze ifake umsele endaweni ehlangene phakathi kwesikhunta esingaphezulu nomzimba, bese kufakwa umucu werabha ovalekayo ofakwa emseleni. Lo mucu werabha ungasetshenziswa kabusha noma ushintshwe nganoma yisiphi isikhathi. Qeda inkinga yokuvuza okuhlangene komhlabathi.

Umugqa womkhiqizo

Ipharamitha yezobuchwepheshe yomshini wokuphotha isigxobo

| Cha. | Into | Iyunithi | Imodeli | ||

| Isondo eliphindwe kabili | Amasondo amathathu | ||||

| 1 | Intambo yamasondo | 2000 | 2000 | ||

| 2 | Isisekelo samasondo | mm | 950 | 950 | |

| 3 | I-diameter yangaphandle yesondo lokugibela | mm | 600 | 600 | |

| 4 | Ububanzi besondo lokugibela | mm | 84 | ||

| 5 | I-Angelα phakathi kwesikhungo samasondo kanye nomugqa wezikhungo zesikhunta | (°) | 75°-110° | ||

| 6 | Ubukhulu.Ubude besigxobo sikakhonkolo sokubumba | m | 26 | 26 | |

| 7 | I-Max.diameter yesigxobo sikakhonkolo sokubumba | Ukuphela kwenduku eyi-conical | mm | 500 | 500 |

| Induku yobubanzi obulinganayo | mm | 600 | 600 | ||

| 8 | Amandla emoto | km | 45kw | 55kw | |

| 9 | Ibanga lesivinini se-final drive shaft | rpm | 60-1000 | 60-1000 | |

| 10 | Ububanzi be-shaft | mm | 130 | 130 | |

| 11 | Impahla yesisekelo | Insimbi yokusakaza | Insimbi yokusakaza | ||

| Idayamitha yangaphakathi yesiphetho esiphezulu(mm) | Ubude(m) | Ububanzi Besondo Eligijimayo(mm) | Nyathela(mm) |

| 150 | 6-11 | 600 | 2000 |

| 190 | 7~15 | 600 | 2000 |

| 230 | 6~12 | 650 | 2000 |

| 270 | 6~10 | 650 | 2000 |