0102030405

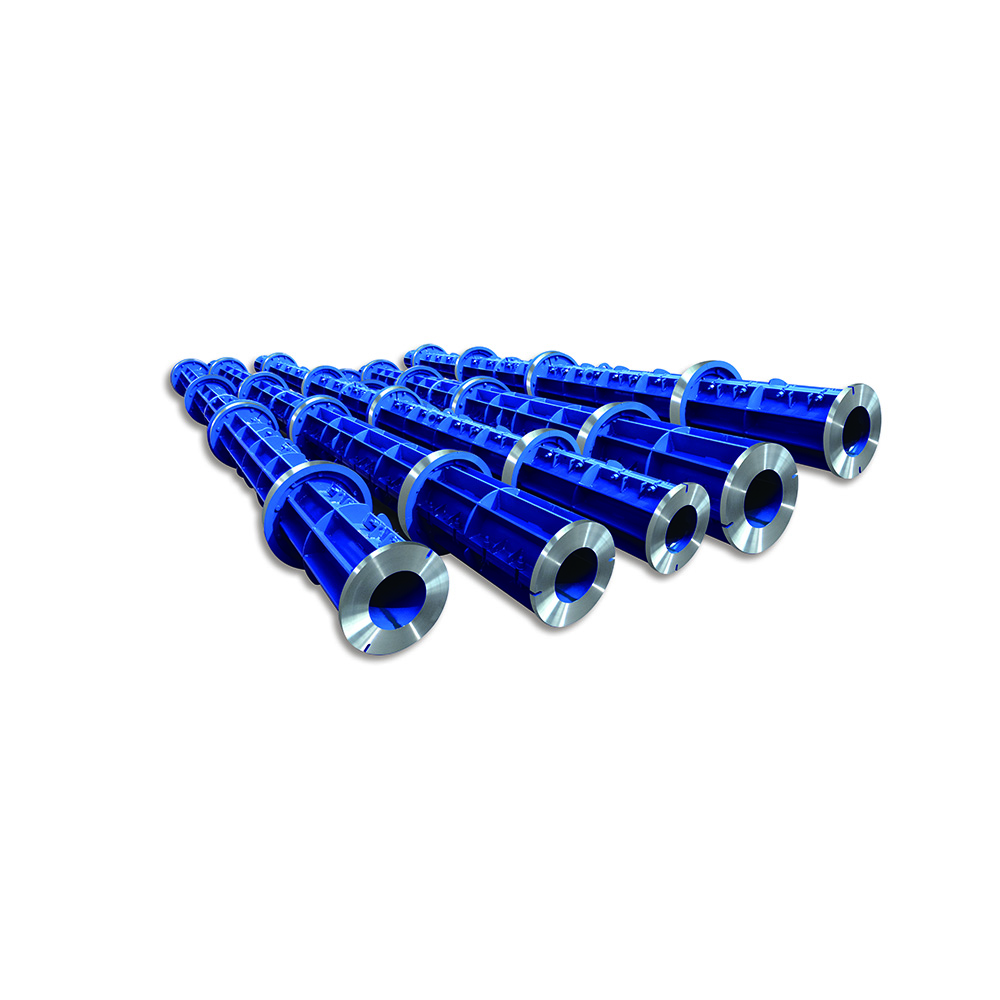

Concrete pole spinning machine

main features

For clamping the joint in the process of the mold running wheels due to imprecise over end of a round, mold pulp mold is not straight caused by accumulated more, cause mold beat, intensifying the centrifuge roller and die wear and damage, in the process of production to strengthen the attention.

Meanwhile, the centrifuge base wheel should be paid more attention to wheel shift will affect the service life of the mold running wheel, serious lead to fly, to be highly valued.Centrifuge is driven by motor drive shaft rotating, make the centrifugal active wheel rotate, active wheel friction produced by touching with the mold running wheel driven the mold rotate. In the process of mold rotation, the concrete in the mold under the action of centrifugal force is uniformly distributed along the mold inwall, and close-grained, gradually through the low speed, middle low, medium, medium high, high-speed stage centrifugal molding, to make the concrete, steel effectively combine to form a reinforced concrete pole preliminary. Due to the working principle of centrifuge is through the mold with the center line of the itself as the axis of rotation of the centrifugal force to make concrete centrifugal molding, so the mold running wheel axis roundness and straightness for mold centrifugal molding is of great significance.

For clamping the joint in the process of the mold running wheels due to imprecise over end of a round, mold pulp mold is not straight caused by accumulated more, cause mold beat, intensifying the centrifuge roller and die wear and damage, in the process of production to strengthen the attention.

Meanwhile, the centrifuge base wheel should be paid more attention to wheel shift will affect the service life of the mold running wheel, serious lead to fly, to be highly valued.