0102030405

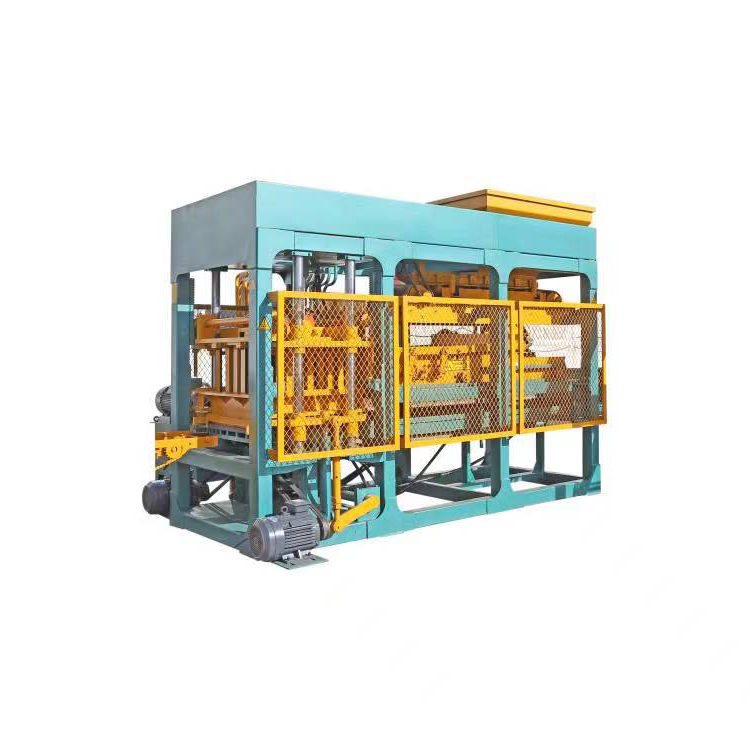

QT6-15 hydraulic concrete block making machine

main features

This model has the following features:

1. The whole process adopts PLC intelligent control and human-machine interface dialogue system, which is easy to analyze the accidental signal, fault diagnosis and parameter setting, and ensure the best operation effect of the machine.

2. Hydraulic system drive

3. A multi-purpose machine, a wide range of production: concrete hollow block, cement solid block, interlock block, paving brick, color street brick, roadside brick.

4. Hydraulic block building machine, so it can produce stronger and better quality bricks.

5. Automatic production line, saving manpower, large output.

6. Forced feeding device: In the process of moving the feeding box to the mold box, the pumping fork works quickly, and finally ensures the uniformity of material feeding and the consistency of product strength.

7. Expand the usable area of the workbench: The application of advanced vibration technology makes the workbench larger and greatly improves productivity.

8. Special vibration type: the pressure and flow of the hydraulic system are controlled by the computer; Vertical frequency conversion. The excessive hydraulic oil is converted into vibration power, thus basically eliminating energy waste.

9. Reasonable vibration distribution: the mold box is fixed on the vibration table through the drawing mold cylinder, and the indenter is equipped with a special vibrator. The joint vibration of the workbench and the mold increases the vibration speed, making the concrete liquefied and vented rapidly, and the final product reaches high density and high strength.

Product specification

| Overall Size | 4410(L)x2000(w)x2510(H)mm |

| Cycle | 15 Seconds |

| Carriage Size | 900(L)x680(W)x25(H)mm |

| Vibration Frequency | 4000-4800r/Min |

| Electrical source | 380V/50Hz(adjustable) |

| Power | 36.4KW |

| Total Mass | 7000KGS |

Product capacity

| Block Name | Size | QTY/mould | QTY/hour | QTY/8hour |

| Hollow block | 400*200*200mm | 6 pcs | 1440 pcs | 11520 pcs |

| Hollow block | 400*150*200mm | 8 pcs | 1920 pcs | 15360 pcs |

| Ripple shape | 250*250*60mm | 6 pcs | 1440 pcs | 11520pcs |

| Zig zag | 250*112.5*60mm | 20 pcs | 4800 pcs | 38400 pcs |

| Rectangle | 200*100*60mm | 20 pcs | 4800 pcs | 38400 pcs |